Coatings

For better protection against corrosion, Ilurco® sheets are subjected to different treatments depending on the environment in which they are going to work. Choose your type of coating according to the content of the deposit.

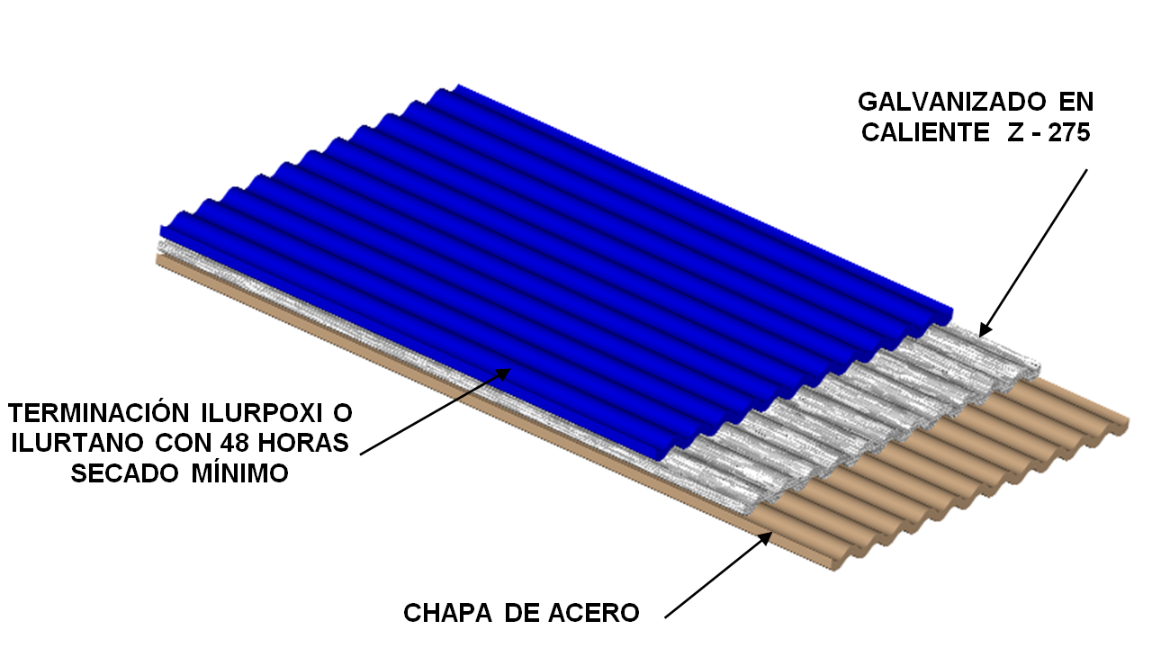

The sheet metal used in Ilurco® tanks is hot dip galvanized by continuous immersion following the EN 10346: 15 / EN 10143: 07 standards.

The minimum protection applied to the sheets of Ilurco® tanks is Z-275, which means an application of 275 gr./m2, which is equivalent to a zinc thickness of 38.5 microns.

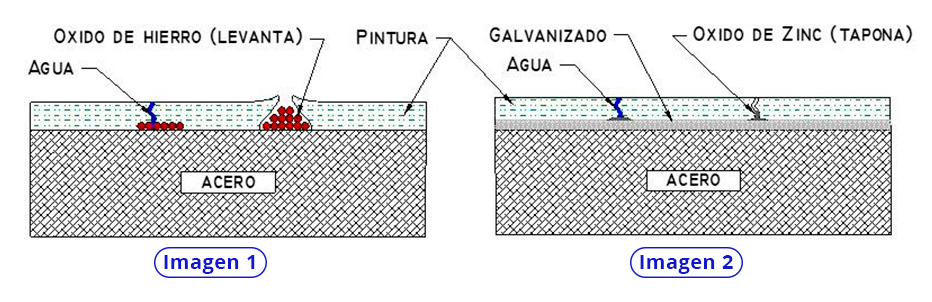

According to studies carried out by independent entities, the most effective system for the protection of the steel used today is the duplex system. These studies show that the corrosion resistance of a steel protected according to the duplex system is much greater than that which would be obtained if we add the duration of each system component of it separately. In other words, a galvanized steel only and a painted steel on a non-galvanized base. This is because the paints have a degree of porosity that allows the water to get through and reach the steel.

When this steel is not galvanized, iron oxide and corrosion is produced and that increases the volume, lifting the paint and speeding up the process, if there is a galvanized base underneath, the zinc oxide will produce a protective layer that will clog the pore of the paint but without uprisings, stopping the corrosion. In the case that it is only galvanized, we also have less protection since zinc is exposed to external agents directly, so Zinc oxide is produced much more easily and the protective layer doesn’t last too long.

- Coating on non-galvanised steel. Once the water gets in touch with steel, rust (iron oxide) increases in volume and cracks the paint, accelerating the corrosion process by easing the access of corrosives to the surface of steel.

- Coating on galvanised Steel. When water gets in touch with the galvanised steel surface, zinc oxide acts as a corrosion protection, preventing the coating deterioration.

Our R&D department has developed various epoxy and polyurethane coatings to meet specific requirements depending on use. Some of the most impressive performance requirements of the ILURCO coatings includes: a high adhesion to galvanised surfaces that it is second to none and an outstanding elasticity, which is higher than regular coating international standards. These properties make of ILURCO coating the ideal choice for a broad number of uses under extreme conditions, protecting surfaces from micro-cracking and the damage responsible for corrosion. This coating meets are applied inside the factory using a chain automatized process following EN ISO 12944-5 (2018) regulation.

STRUCTURE OF THE DUPLEX SYSTEM (SAME IN BOTH SIDES)

Application limits inside the EN ISO 12944-5 (2018) regulation are shown in the next tables. As well as the Ilurco Coatings used to comply with it.

ILURCO’s R&D recommends the Duplex System (galvanising + epoxy) for low or medium corrosivity categories, described in the regulation as C2 and C3 (ie. Clean or hard water). For high and very high corrosivity categories as C4 and C5, the regulation recommends applying a priming coat and one or two epoxy finishing coats.

This is ILURCO’s TRIPLEX SYSTEM that consists of the application of three coats: galvanising, priming coat and several finishing coats. As priming coat, ILURCO’S R&D has developed ILURPROXI BASICO that offers a high waterproof protection with high film thickness and excellent adherence on galvanised surfaces. It is suitable to be used with a wide range of coating products. Besides, it provides a high impermeability to water.

On this primer layer, one or two coats are applied, depending on the use, of the most convenient coating depending on the water to be contained, which allows us to fully exploit the best properties of each product. The finishing layer is responsable for resisting the most aggressive elements contained in the water and from the primer coat, the adherence between the base and the finishing layer.

STRUCTURE OF THE TRIPLEX SYSTEM

CHOOSE YOUR TYPE OF COATING

Normal conditions

- Galvanized

- Ilurpoxi® Basic

- Ilurpoxi® Celeste

- Ilurpoxi® Potable

- Ilurpetrol®

- Specials

Mild Severe Conditions

- Galvanized

- Ilurpoxi® Basic

Normal conditions

- Ilurpoxi® Celeste

- Ilurpoxi® Potable

- Ilurpetrol®

- Specials

Mild Severe Conditions

- Ilurpoxi® Celeste

- Ilurpoxi® Potable

Normal conditions

- Ilurpetrol®

Severe Conditions

- Specials

Not recommended

- Galvanized

- Ilurpoxi® Basic

Mild Severe Conditions

- Ilurpoxi® Celeste

- Ilurpoxi® Potable

Normal conditions

- Ilurpetrol®

Severe Conditions

- Specials

Not Recommended

- Galvanized

- Ilurpoxi® Basic

Mild Severe Conditions

- Ilurpoxi® Celeste

- Ilurpoxi® Potable

Normal conditions

- Ilurpetrol®

Severe Conditions

- Specials

Not recommended

- Galvanized

- Ilurpoxi® Basic

Normal conditions

- Ilurpoxi® Potable

Severe Conditions

- Specials

Not Recommended

- Galvanized

- Ilurpoxi® Basic

- Ilurpoxi® Celeste

- Ilurpetrol®

Mild Severe Conditions

- Galvanized

- Ilurpoxi® Celeste

- Ilurpoxi® Potable

Normal conditions

- Specials

Severe Conditions

- Ilurpetrol®

Not Recommended

- Ilurpoxi® Basic

Mild Severe Conditions

- Ilurpoxi® Basic

Normal conditions

- Ilurpoxi® Celeste

- Ilurpoxi® Potable

- Ilurpetrol®

Condiciones Severas

- Specials

Not Recommended

- Galvanized

Coating selection and application tables

| ILURCO TANK COATINGS | ||

| PRODUCT | DESCRIPTION | APPLICATION |

| ILURPOXI BASICO | Epoxy coating with outstanding adhesion properties on all type of surfaces. To use as priming coat to de subsequent coats or as topcoat for non-corrosive water storage. |

|

| ILURPOXI CELESTE | Protection epoxy coating for water, wastewater or corrosive water storage. Ensures high galvanising durability. |

|

| ILURPOXI BLANCO | Provides a highly resistant epoxy coating and ideal for food storage. Suitable for potable water storage. |

|

| ILURPETROL | Extra thick epoxy coating that offers the most resistant coating possible for petrochemical and oily water storage. |

|

| ILURTANO VERDE |

Green polyurethane coating for a perfect external finish. Dual function as tank protection coating and decoration. Its pine-olive green colour makes tanks look good and blends them with the environment. |

|

| ESPECIALES | Extra thick coating that contains ceramic particles and offers protection from chemical corrosion, as well as corrosive water. To use for very corrosive water storage or for tanks under physical abrasion conditions. Ensures high durability with little maintenance. |

|

TABLE OF COATINGS SELECTION RECOMMENDATIONS ACCORDING THE APPLICATION.

|

Coating suitability according to use and exposure conditions |

||||||||||

| X Recommendable | O Mild Conditions | *Moderate Conditions | ▲ Severe Conditions | |||||||

| Tank Coating | Storage tank may contain | |||||||||

| Neutral fresh water | Dirty, hard water or with carbonates | Wastewater. Industrial water treatment | Food industry wastewaters | Corrosive, acidic water | Potable water | Petrochemical or oil water | Seawater | |||

| Ilurpoxi® Básica |

* |

O |

X |

X |

X |

X |

X |

O |

||

| Ilurpoxi® Celeste |

* |

* |

O |

* |

O |

X |

O |

* |

||

| Ilurpoxi® Potable |

* |

* |

O |

* |

O |

* |

O |

* |

||

| Ilurpetrol® |

* |

* |

* |

* |

* |

X |

▲ |

* |

||

| Specials |

* |

* |

▲ |

▲ |

▲ |

▲ |

* |

▲ |

||

| PVC Base |

* |

* |

* |

* |

* |

* |

X |

* |

||

Table D.1 – Paint system for galvanised steel by corrosivity categories C2 to C5

TABLE FOR CONVERSION TO ILURCO SYSTEM. OUTER FACE OF THE TANK

|

System Number |

Corrosivity category |

First coating layer |

Next layer (s) |

N° total layers |

Durabilitya |

|||||||||||

|

LAYER 1 |

N° of layers |

LAYER 2 |

s |

m |

h |

vh |

||||||||||

| G2.01 |

C2 |

ACRILURCO |

1 |

1 |

X |

X |

X |

|||||||||

| G2.02 |

– |

1 |

– |

2 |

X |

X |

X |

X |

||||||||

| G2.03 |

ILURPOXI BÁSICA |

1 |

ILURTANO |

1 a 2 |

X |

X |

X |

X |

||||||||

| G3.01 |

C3 |

ILURTANO |

1 |

1 |

X |

X |

||||||||||

| G3.02 |

ILURPOXI BÁSICA |

1 |

ILURTANO |

1 a 2 |

X |

X |

X |

|||||||||

| G3.03 |

– |

1 |

– |

2 |

X |

X |

X |

|||||||||

| G3.04 |

ILURPOXI BÁSICA |

1 |

ILURTANO |

2 |

X |

X |

X |

X |

||||||||

| G3.05 |

– |

1 |

– |

2 a 3 |

X |

X |

X |

X |

||||||||

| G4.01 |

C4 |

ILURTANO |

1 |

|

1 |

X |

||||||||||

| G4.02 |

ILURPOXI BÁSICA |

1 |

ILURTANO |

1 a 2 |

X |

X |

||||||||||

| G4.03 |

– |

1 |

– |

2 |

X |

X |

||||||||||

| G4.04 |

ILURPOXI BÁSICA |

1 |

ILURPOXI CELESTE |

2 |

X |

X |

X |

|||||||||

| G4.05 |

– |

1 |

– |

2 a 3 |

X |

X |

X |

|||||||||

| G4.06 |

ILURPOXI BÁSICA |

1 |

ILURPOXI CELESTE |

2 a 3 |

X |

X |

X |

X |

||||||||

| G5.01 |

C5 |

ILURPOXI BÁSICA |

1 |

ILURTANO |

1 a 2 |

X |

||||||||||

| G5.02 |

– |

1 |

– |

2 |

X |

|||||||||||

| G5.02 |

ILURPOXI BÁSICA |

1 |

ILURPOXI CELESTE |

2 |

X |

X |

||||||||||

| G5.03 |

– |

1 |

– |

2 a 3 |

X |

X |

||||||||||

| G5.04 |

ILURPOXI BÁSICA |

1 |

ILURPETROL |

2 a 3 |

X |

X |

X |

|||||||||

| G5.05 |

ILURPOXI BÁSICA |

1 |

ILURPETROL |

2 a 3 |

X |

X |

X |

X |

||||||||

|

ILURCO SYSTEM |

BASE |

FINISH |

TOTAL HANDS |

ISO 12944-5 SYSTEMS |

||||||||||||

| DUPLEX ACRILURCO |

– |

ACRILURCO |

1 |

G2.01 |

|

|

|

|

||||||||

| DUPLEX ILURTANO |

– |

ILURTANO |

1 |

G3.01 |

G4.01 |

|

|

|

||||||||

| TRIPLEX ILURTANO |

ILURPOXI BÁSICA |

ILURTANO |

2 |

G2.03 |

G3.02 |

G3.04 |

G4.02 |

G5.01 |

||||||||

| TRIPLEX ILURPOXI CELESTE |

ILURPOXI BÁSICA |

ILURPOXI CELESTEc |

3 |

G4.04 |

G4.06 |

G5.02 |

|

|

||||||||

| TRIPLEX ILURPETROL |

ILURPOXI BÁSICA |

ILURPETROLc |

3 |

G5.04 |

G5.05 |

|

|

|

||||||||

| a Durability in this case is related to the adherence of the paint system to the hot-dip galvanized steel substrate. In the event that the paint system is damaged, the remaining galvanised layer provides additional protection to the steel.

c These categories are intended for buried deposits. When an epoxy resin is used as a topcoat on the outside of an overhead tank, a topcoat for UV protection is necessary, for example ILURTANO or ACRILURCO. |

||||||||||||||||

Table D.1 – Paint system for galvanized steel by corrosivity categories C2 to C5

TABLE OF CONVERSION TO ILURCO SYSTEM. INNER FACE OF THE DEPOSIT